Service

Leading Edge stands at the forefront of precision component machining, delivering exceptional quality components for the world's most demanding industries.

Our services

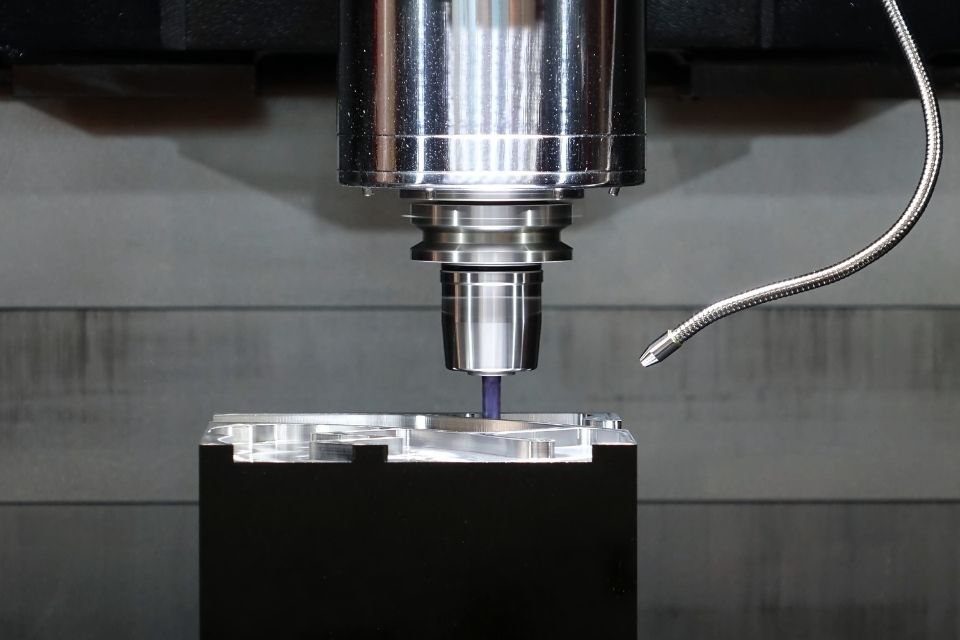

CNC Machining at Leading Edge

Leading Edge stands at the forefront of precision CNC machining, delivering exceptional quality components for the world’s most demanding industries.

- Tolerances up to ±0.005 mm

- Materials from platics, metals to exotic alloys

- Complex geometries and features

- Full inspection and certification

- Rapid prototyping available

- Complete finishing services

+86 13826962122

What We Offer

Comprehensive machining solutions

Crafting high-quality components to the tightest tolerances, our precision CNC machining ensures consistent results for critical applications in medical, aerospace, and semiconductor industries.

We deliver durable, precise, and cost-effective solutions for a wide range of sheet metal fabrication processes including shaping, cutting, bending, and assembling metal sheets into custom parts or products.

From rapid prototyping to production-grade parts, our advanced cutting-edge 3D printing provide precision, efficiency, and versatility to meet the demands of modern manufacturing.

Vacuum Casting process is ideal for creating prototypes, pre-production runs, or functional parts. It ensures precise replication of the master model, and achieving excellent surface finishes.

Injection Molding is ideal for producing durable parts at scale with minimal material waste and exceptional repeatability. It ensure consistency, durability, and cost-efficiency in every project.

Leading Edge offers production runs tailored for prototypes and small batches, combining flexibility with premium quality. Perfect for industries requiring high-precision parts in lower quantities.

Why Choose us

Why Leading Edge

At Leading Edge, we pride ourselves on engineering, delivering unparalleled quality, tailored solutions, and exceptional customer support.

Our team of expert engineers and technicians brings decades of combined experience in precision manufacturing, ensuring optimal solutions for every project.

State-of-the-art 5-axis CNC machines, EDM systems, and precision measuring equipment deliver unmatched accuracy and consistency.

Extensive experience working with diverse materials including exotic alloys, medical-grade materials, and aerospace-certified metals.

Rigorous quality management system with comprehensive inspection protocols and full material traceability for every component.

Our lean manufacturing processes and dedicated project managers ensure quick turnaround times without compromising quality.

We work closely with clients throughout the entire process, from initial design concept to final delivery.

How it works

When you need experience, we have it covered.

Our streamlined process ensures precision, efficiency, and complete satisfaction at every step.

Consultation what you need.

Our engineering team carefully reviews your CAD files, technical drawings, and specifications, engaging in detailed discussions about material choices, tolerance requirements, and surface finish needs.

Quote and Order Confirmation

You’ll receive a comprehensive quote that includes all specifications, deliverables, quality standards. Upon your approval, we move into the confirmation phase where all project details are thoroughly reviewed and finalized.

Manufacturing & Quality Control

During production, we maintain rigorous quality control through continuous monitoring and inspection processes. Our state-of-the-art CMM equipment verifies critical dimensions, while expert technicians conduct thorough surface finish inspections.

What they say about us

Semper aliquet primis venenatis platea viverra magna praesent sed mattis netus nostra.

COMMON QUESTIONS

Frequently asked questions

Feel free to contact us if you have any questions.

Yes, we specialize in small-batch production to meet your specific needs, ensuring consistent quality and efficiency for custom projects.

We work with a wide range of materials, including metals such as aluminum, stainless steel, titanium, and brass, as well as engineering plastics like PEEK, Delrin, and more.

Yes, we provide free DFMA (Design for Manufacturing and Assembly) feedback to help optimize your designs for the CNC machining process. This ensures that your parts can be produced efficiently and cost-effectively.

You can request a quote by filling out the “Request a Quote” form on our website or contacting us directly via email or phone. Please provide your CAD files and any relevant specifications for an accurate quote.

Yes, we offer rapid prototyping to help you quickly create functional prototypes and validate your designs. Our CNC prototyping services deliver parts that match the material properties of final production components.

Our CNC machining processes can achieve tolerances as tight as ±0.005 mm depending on the complexity of the part and material used. We’ll discuss specific tolerances during the design phase to meet your project requirements.

We accept a variety of CAD file formats, including .STEP, .STL, .DWG, .DXF, IGES, and Zip. If you have a different format, let us know, and we’ll work to accommodate it.

Our typical response time for quotes is 24-48 hours. However, more complex projects may take slightly longer for thorough assessment.

Lead times vary depending on the complexity and volume of the project. For most orders, we provide a detailed timeline after assessing your requirements.

Yes, we provide global shipping services, delivering parts to clients worldwide. We work with reliable logistics partners to ensure that your components arrive safely and on time.

GET IN TOUCH

Whenever you need us, we’re here for you.

Got a project in mind? Contact us today to discover how Leading Edge can bring your ideas to life with precision and excellence.

Dongguan, Guangdong, China

Phone : +86 13826962122