Gear and Transmission

Leading Edge stands at the forefront of precision component machining, delivering exceptional quality components for the world's most demanding industries.

OUR SERVICES

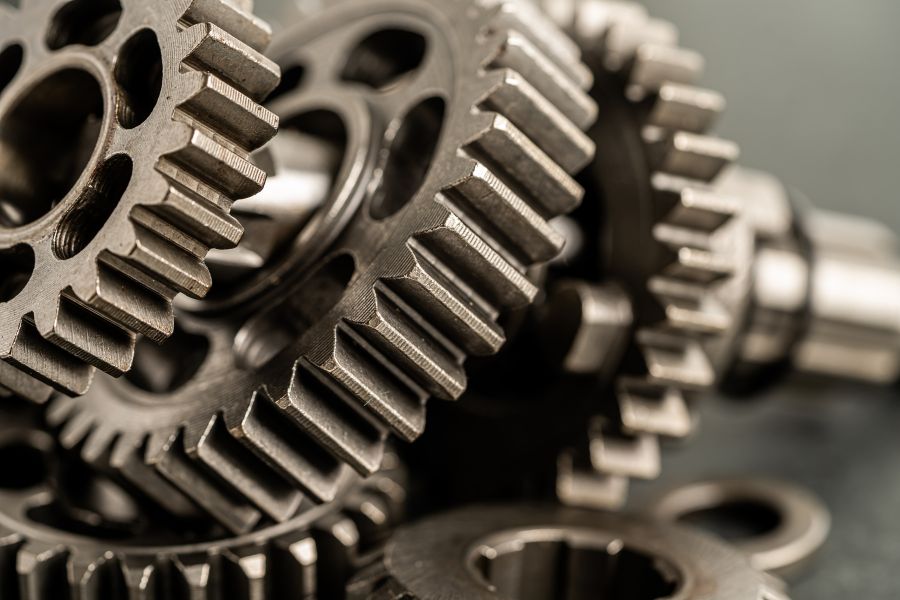

Gear and Transmission

At Leading Edge, we specialize in delivering high-performance gear and transmission solutions designed to meet the demanding requirements of modern industries. From precision manufacturing to rigorous quality assurance, our comprehensive services ensure optimal performance, durability, and reliability for your mechanical systems.

Solution

Our Gear and Transmission Solutions

Gears and transmission systems are integral to the functionality of machines, converting energy into motion efficiently. They encompass a range of components, including spur gears, helical gears, bevel gears, worm gears, and planetary systems, each tailored for specific applications. Our expertise spans from individual gear manufacturing to complete transmission assembly, providing solutions for industries such as automotive, aerospace, robotics, and industrial machinery.

- Gear Types

-

- Spur Gears: Simplistic and highly efficient, ideal for low-speed and low-torque applications.

- Helical Gears: Quiet operation and higher load capacity, suited for automotive and industrial uses.

- Bevel Gears: Angular power transmission, common in automotive differentials and power tools.

- Worm Gears: Compact, high-reduction gears with self-locking capabilities.

- Planetary Gears: Efficient multi-gear systems for high torque and compact designs.

- Materials Expertise

-

- Metals: High-strength steels, stainless steel, and alloy steels for durability and load-bearing capacity.

- Non-Metals: Engineering plastics like POM and nylon for lightweight, low-noise applications.

- Specialty Materials: Heat-resistant alloys, titanium, and composites for specialized environments.

- Manufacturing Processes

-

-

Design and Engineering

- Collaborate with our expert team to optimize gear designs for performance, efficiency, and manufacturability.

- Leverage advanced CAD and simulation software to validate designs before production.

-

Material Selection

- Choose from our extensive range of high-quality materials based on the application’s requirements.

-

Precision Machining

- Utilize state-of-the-art CNC machining, hobbing, and grinding equipment for precise gear cutting and shaping.

-

Heat Treatment

- Apply tailored heat treatment processes to enhance the material’s mechanical properties.

-

Inspection and Quality Control

- Perform dimensional checks, surface finish evaluations, and functional testing to ensure all gears meet stringent quality standards.

-

Assembly and Testing

- Assemble complete transmission systems and test them under simulated operating conditions to verify performance and reliability.

-

- Spur Gears: Simplistic and highly efficient, ideal for low-speed and low-torque applications.

- Helical Gears: Quiet operation and higher load capacity, suited for automotive and industrial uses.

- Bevel Gears: Angular power transmission, common in automotive differentials and power tools.

- Worm Gears: Compact, high-reduction gears with self-locking capabilities.

- Planetary Gears: Efficient multi-gear systems for high torque and compact designs.

- Metals: High-strength steels, stainless steel, and alloy steels for durability and load-bearing capacity.

- Non-Metals: Engineering plastics like POM and nylon for lightweight, low-noise applications.

- Specialty Materials: Heat-resistant alloys, titanium, and composites for specialized environments.

-

Design and Engineering

- Collaborate with our expert team to optimize gear designs for performance, efficiency, and manufacturability.

- Leverage advanced CAD and simulation software to validate designs before production.

-

Material Selection

- Choose from our extensive range of high-quality materials based on the application’s requirements.

-

Precision Machining

- Utilize state-of-the-art CNC machining, hobbing, and grinding equipment for precise gear cutting and shaping.

-

Heat Treatment

- Apply tailored heat treatment processes to enhance the material’s mechanical properties.

-

Inspection and Quality Control

- Perform dimensional checks, surface finish evaluations, and functional testing to ensure all gears meet stringent quality standards.

-

Assembly and Testing

- Assemble complete transmission systems and test them under simulated operating conditions to verify performance and reliability.

Why Choose us

Why Leading Edge

At Leading Edge, we pride ourselves on engineering, delivering unparalleled quality, tailored solutions, and exceptional customer support.

Rapid Response

We understand the importance of speed in the automotive industry. Our advanced prototyping processes allow us to produce high-quality parts quickly, enabling faster iterations and reduced lead times in your development cycle.

Material Expertise

We offer a wide range of materials, including steel, aluminum, and advanced composites, to ensure that our automotive components provide exceptional durability and performance, even in the most demanding environments.

Quality Assurance

At Leading Edge, we prioritize quality in every aspect of our manufacturing process. Each component undergoes rigorous quality checks to ensure it meets the highest standards of performance and reliability.

Custom Solutions

We understand that every application is unique. Our engineering team works closely with you to design and manufacture custom automotive components tailored to your specific needs and performance requirements.

With Leading Edge, you’ll find more than a manufacturer—you’ll discover a committed partner for achieving your most ambitious goals.

Ready to get started?

Let Leading Edge be your trusted partner for precision CNC milling. Our expertise, advanced technology, and commitment to quality ensure that your parts are manufactured to the highest standards. Contact us today to discuss your project or request a free quote and learn how we can bring your designs to life with exceptional precision.

How it works

When you need experience, we have it covered.

Our streamlined process ensures precision, efficiency, and complete satisfaction at every step.

Consultation what you need.

Our engineering team carefully reviews your CAD files, technical drawings, and specifications, engaging in detailed discussions about material choices, tolerance requirements, and surface finish needs.

Quote and Order Confirmation

You’ll receive a comprehensive quote that includes all specifications, deliverables, quality standards. Upon your approval, we move into the confirmation phase where all project details are thoroughly reviewed and finalized.

Manufacturing & Quality Control

During production, we maintain rigorous quality control through continuous monitoring and inspection processes. Our state-of-the-art CMM equipment verifies critical dimensions, while expert technicians conduct thorough surface finish inspections.

GET IN TOUCH

Whenever you need us, we’re here for you.

Got a project in mind? Contact us today to discover how Leading Edge can bring your ideas to life with precision and excellence.

Dongguan, Guangdong, China

Phone : +86 13826962122