OUR SERVICES

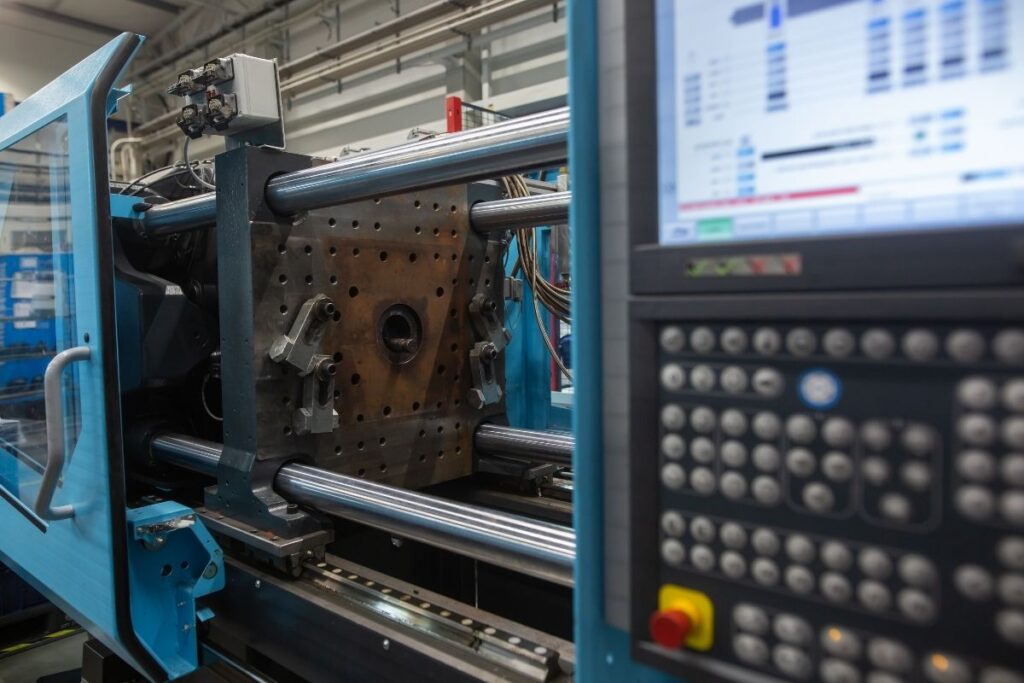

Injection Molding

At Leading Edge, we offer high-precision injection molding services to deliver custom plastic components tailored to meet your industry’s requirements. With state-of-the-art equipment, a wide selection of materials, and advanced expertise, we ensure consistency, durability, and cost-efficiency in every project, whether for prototyping or high-volume production.

Capabilities

Our capabilities

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity, cooled, and solidified to create precise and complex shapes. This method is ideal for producing durable parts at scale with minimal material waste and exceptional repeatability.

- Custom Mold Design: Tailored to your specifications using advanced CAD/CAM software.

- Multi-Cavity Molds: For high-volume production and efficient manufacturing.

- Insert Molding: Integration of metal or other components into the mold for hybrid designs.

- Overmolding: Layering different materials to achieve complex functional or aesthetic properties.

- Clamping Forces: Ranging from 50 to 500 tons, allowing for the production of parts with a wide variety of sizes and weights.

- Shot Sizes: From a few grams to several kilograms, catering to both small and large components.

- Precision Controls: Advanced machines with real-time monitoring ensure consistent quality and tight tolerances.

- High-Volume Production: Efficient and cost-effective for large-scale manufacturing.

- Low-Volume Runs: Flexible solutions for prototypes or niche applications.

- Thin-Wall Molding: Precision molding for lightweight, durable parts.

- Complex Geometries: Capability to produce intricate designs with undercuts, threads, and tight tolerances.

- Assembly: Ultrasonic welding, press-fitting, or mechanical assembly.

- Painting and Printing: Custom branding or labeling for your parts.

- Surface Finishing: Polishing, texturing, or coatings to enhance appearance and performance.

Material

Our materials for Injection Molding

At Leading Edge, we provide a wide range of materials for your needs.

- ABS (Acrylonitrile Butadiene Styrene): Durable, impact-resistant, and versatile, ideal for automotive and consumer products.

- Polycarbonate (PC): High strength and heat resistance, suitable for medical and industrial applications.

- Nylon (PA): Lightweight, wear-resistant, and excellent for mechanical components.

- Polyethylene (PE): Low-cost, chemical-resistant material for packaging and consumer goods.

- Polypropylene (PP): Flexible and fatigue-resistant, commonly used in medical and automotive industries.

- Polystyrene (PS): Affordable and easy to mold, ideal for disposable products and packaging.

- POM (Polyoxymethylene or Acetal): High stiffness, low friction, and excellent dimensional stability for gears and bearings.

- PEEK (Polyether Ether Ketone): High-performance material for aerospace and medical parts exposed to extreme temperatures and stress.

- Polyphenylene Sulfide (PPS): Superior chemical resistance and thermal stability for industrial applications.

- TPU (Thermoplastic Polyurethane): Flexible, durable, and ideal for seals, gaskets, and ergonomic parts.

- TPE (Thermoplastic Elastomer): Combines rubber-like flexibility with plastic-like processing.

- Glass-Filled Plastics: Enhanced stiffness and strength for demanding structural applications.

- Flame-Retardant Plastics: Compliant with safety standards for electrical and electronic components.

- Medical-Grade Plastics: Biocompatible materials for healthcare and pharmaceutical applications.

Why Us

Why choose us

At Leading Edge, we pride ourselves on engineering, delivering unparalleled quality, tailored solutions, and exceptional customer support.

Rapid Turnaround

Experience quick prototype-to-production transitions with our streamlined workflows. We typically deliver orders within 2-4 weeks, depending on complexity and quantity.

Design Flexibility

Make design modifications easily without the constraints of high-volume tooling. Our agile manufacturing approach accommodates design iterations and improvements.

Quality Assurance

At Leading Edge, we prioritize quality in every aspect of our manufacturing process. Each component undergoes rigorous quality checks to ensure it meets the highest standards of performance and reliability.

Cost-Effective Production

Minimize your investment in tooling and inventory while maintaining high quality. Our efficient processes and lean manufacturing principles help reduce costs without compromising precision.

With Leading Edge, you’ll find more than a manufacturer—you’ll discover a committed partner for achieving your most ambitious goals.

Ready to get started?

Let Leading Edge be your trusted partner for precision CNC milling. Our expertise, advanced technology, and commitment to quality ensure that your parts are manufactured to the highest standards. Contact us today to discuss your project or request a free quote and learn how we can bring your designs to life with exceptional precision.

How it works

When you need experience, we have it covered.

Our streamlined process ensures precision, efficiency, and complete satisfaction at every step.

Consultation what you need.

Our engineering team carefully reviews your CAD files, technical drawings, and specifications, engaging in detailed discussions about material choices, tolerance requirements, and surface finish needs.

Quote and Order Confirmation

You’ll receive a comprehensive quote that includes all specifications, deliverables, quality standards. Upon your approval, we move into the confirmation phase where all project details are thoroughly reviewed and finalized.

Manufacturing & Quality Control

During production, we maintain rigorous quality control through continuous monitoring and inspection processes. Our state-of-the-art CMM equipment verifies critical dimensions, while expert technicians conduct thorough surface finish inspections.

GET IN TOUCH

Whenever you need us, we’re here for you.

Got a project in mind? Contact us today to discover how Leading Edge can bring your ideas to life with precision and excellence.

Dongguan, Guangdong, China

Phone : +86 13826962122