OUR SERVICES

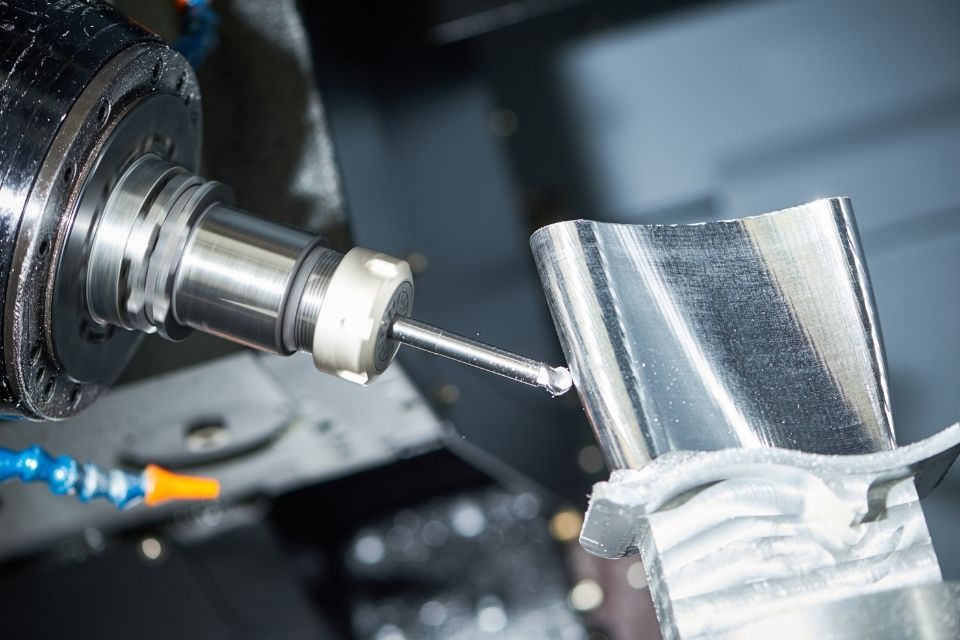

Precision CNC machining service

Our state-of-the-art CNC machining solutions deliver exceptional accuracy and surface quality for your most demanding components. With advanced programming capabilities and expert machinists, we handle complex geometries and tight tolerances across diverse materials. Our precision machining services support industries from medical devices to aerospace, ensuring every component meets exact specifications.

Capabilities

Our capabilities

Leading Edge delivers exceptional precision CNC machining services, combining advanced technology with expert craftsmanship to produce high-quality components that meet the most demanding specifications.

- Parts Size

-

- Minimum: 2mm × 2mm × 2mm

- Maximum: 800mm × 800mm × 500mm

- Optimal size range: 5mm – 400mm

- Tolerance

-

- Standard Tolerances: ±0.05 mm (approx. ±0.002 in).

- Tight Tolerances: Up to ±0.005 mm (approx. ±0.0002 in), depending on the complexity of the part and material type.

- Custom Tolerances: Available upon request, based on specific project needs.

- Min. Feature Size

-

- Standard tolerance: ±0.05mm

- Precision tolerance: ±0.01mm

- Ultra-precision tolerance: ±0.005mm

- Geometric tolerances: According to ISO 1101 standards

- Concentricity: 0.01mm

- Flatness: 0.01mm

- Threads and Holes

-

We can adapt to any standard thread size and customized threads.

- Minimum hole diameter: 0.5mm

- Maximum depth-to-diameter ratio: 10:1

- Thread sizes: M1.6 to M36

- Thread tolerance: 6g/6H

- Minimum threaded depth: 2mm

- Blind hole minimum depth: 0.8mm

- Burrs and Chamfers

-

Deburring by default, chamfering according to your requirements.

- Chamfer range: 0.2mm – 3mm at 45°

- Custom angle chamfers available

- Edge rounding: R0.2 – R3

- Custom edge profiles

- Surface Finish Options

-

- Surface roughness: Ra 0.2μm – 3.2μm

- As-Milled: Standard surface finish with visible tool marks, typically Ra 3.2 µm, The minimum can be Ra 0.2um

- Bead Blasting: Creates a uniform, matte finish on metal surfaces.

- Anodizing: Available in clear or colored options, providing both aesthetic appeal and corrosion resistance for aluminum parts.

- Chemical coating: can be chrome-plated, zinc-plated, nickel-plated and other chemical elements

- Powder Coating: Durable and wear-resistant coating available in a variety of colors.

- Polishing: High-gloss finishes for aesthetic purposes and optical clarity.

- Brushing: Creates a consistent linear texture for a satin finish.

- Custom Finishes: Available upon request, based on specific client needs.

- Hard chrome plating

- Electroless nickel plating

- Passivation

- Black oxide coating

- Lead Time

-

- Standard Turnaround: 5-10 business days, depending on part complexity and quantity.

- Expedited Services: 2-5 business days for urgent projects with shorter lead times.

- Large Production Runs: Lead time varies based on volume, but we work closely with clients to ensure on-time delivery for every project.

- The lead time depends on the customer’s requirements. For Urgent cases can be given more priority, based on customer needs.

- Minimum: 2mm × 2mm × 2mm

- Maximum: 800mm × 800mm × 500mm

- Optimal size range: 5mm – 400mm

- Standard Tolerances: ±0.05 mm (approx. ±0.002 in).

- Tight Tolerances: Up to ±0.005 mm (approx. ±0.0002 in), depending on the complexity of the part and material type.

- Custom Tolerances: Available upon request, based on specific project needs.

- Standard tolerance: ±0.05mm

- Precision tolerance: ±0.01mm

- Ultra-precision tolerance: ±0.005mm

- Geometric tolerances: According to ISO 1101 standards

- Concentricity: 0.01mm

- Flatness: 0.01mm

We can adapt to any standard thread size and customized threads.

- Minimum hole diameter: 0.5mm

- Maximum depth-to-diameter ratio: 10:1

- Thread sizes: M1.6 to M36

- Thread tolerance: 6g/6H

- Minimum threaded depth: 2mm

- Blind hole minimum depth: 0.8mm

Deburring by default, chamfering according to your requirements.

- Chamfer range: 0.2mm – 3mm at 45°

- Custom angle chamfers available

- Edge rounding: R0.2 – R3

- Custom edge profiles

- Surface roughness: Ra 0.2μm – 3.2μm

- As-Milled: Standard surface finish with visible tool marks, typically Ra 3.2 µm, The minimum can be Ra 0.2um

- Bead Blasting: Creates a uniform, matte finish on metal surfaces.

- Anodizing: Available in clear or colored options, providing both aesthetic appeal and corrosion resistance for aluminum parts.

- Chemical coating: can be chrome-plated, zinc-plated, nickel-plated and other chemical elements

- Powder Coating: Durable and wear-resistant coating available in a variety of colors.

- Polishing: High-gloss finishes for aesthetic purposes and optical clarity.

- Brushing: Creates a consistent linear texture for a satin finish.

- Custom Finishes: Available upon request, based on specific client needs.

- Hard chrome plating

- Electroless nickel plating

- Passivation

- Black oxide coating

- Standard Turnaround: 5-10 business days, depending on part complexity and quantity.

- Expedited Services: 2-5 business days for urgent projects with shorter lead times.

- Large Production Runs: Lead time varies based on volume, but we work closely with clients to ensure on-time delivery for every project.

- The lead time depends on the customer’s requirements. For Urgent cases can be given more priority, based on customer needs.

Material

Our materials

At Leading Edge, we provide a wide range of materials for your needs.

- 6061-T6: Excellent general-purpose alloy, ideal for precision parts

- 7075-T6: High-strength aerospace-grade applications

- 5052: Excellent corrosion resistance, marine applications

- 2024: Aircraft structural components

- QC-10: Premium mold-making aluminum

- 304/304L: General purpose, good corrosion resistance

- 316/316L: Medical and marine grade

- 17-4 PH: High-strength, heat-treatable

- 440C: High hardness applications

- 321: High-temperature stability

- 420: Cutlery and surgical instruments

- D2: High wear resistance, cutting tools

- H13: Hot work applications

- A2: Cold work applications

- O1: Oil-hardening applications

- M2: High-speed steel

- P20: Mold and die applications

- C360 Brass: General purpose

- C954 Bronze: Marine applications

- Beryllium Copper: Spring applications

- Phosphor Bronze: Bearing applications

- Tellurium Copper: High conductivity

- Naval Brass: Marine components

- Ti-6Al-4V (Grade 5): Aerospace and medical

- Ti-6Al-4V ELI: Medical implants

- Grade 2: Pure titanium, chemical resistance

- Grade 4: Higher strength pure titanium

- Ti-6Al-7Nb: Medical applications

- Beta titanium alloys

- Inconel 718: High-temperature applications

- Hastelloy: Corrosion resistant

- Monel: Marine applications

- Kovar: Thermal expansion matching

- Invar: Dimensional stability

- MP35N: High-strength medical

- PEEK: High-performance applications

- Delrin/POM: Precision components

- UHMW: Wear applications

- Nylon (PA): Various grades

- PTFE: Low friction applications

- PPS: High-temperature stability

- PVDF: Chemical resistance

Why Choose us

Why Leading Edge

At Leading Edge, we pride ourselves on engineering, delivering unparalleled quality, tailored solutions, and exceptional customer support.

Rapid Response

We understand the importance of speed in the automotive industry. Our advanced prototyping processes allow us to produce high-quality parts quickly, enabling faster iterations and reduced lead times in your development cycle.

Material Expertise

We offer a wide range of materials, including steel, aluminum, and advanced composites, to ensure that our automotive components provide exceptional durability and performance, even in the most demanding environments.

Quality Assurance

At Leading Edge, we prioritize quality in every aspect of our manufacturing process. Each component undergoes rigorous quality checks to ensure it meets the highest standards of performance and reliability.

Custom Solutions

We understand that every application is unique. Our engineering team works closely with you to design and manufacture custom automotive components tailored to your specific needs and performance requirements.

With Leading Edge, you’ll find more than a manufacturer—you’ll discover a committed partner for achieving your most ambitious goals.

Ready to get started?

Let Leading Edge be your trusted partner for precision CNC milling. Our expertise, advanced technology, and commitment to quality ensure that your parts are manufactured to the highest standards. Contact us today to discuss your project or request a free quote and learn how we can bring your designs to life with exceptional precision.

How it works

When you need experience, we have it covered.

Our streamlined process ensures precision, efficiency, and complete satisfaction at every step.

Consultation what you need.

Our engineering team carefully reviews your CAD files, technical drawings, and specifications, engaging in detailed discussions about material choices, tolerance requirements, and surface finish needs.

Quote and Order Confirmation

You’ll receive a comprehensive quote that includes all specifications, deliverables, quality standards. Upon your approval, we move into the confirmation phase where all project details are thoroughly reviewed and finalized.

Manufacturing & Quality Control

During production, we maintain rigorous quality control through continuous monitoring and inspection processes. Our state-of-the-art CMM equipment verifies critical dimensions, while expert technicians conduct thorough surface finish inspections.

GET IN TOUCH

Whenever you need us, we’re here for you.

Got a project in mind? Contact us today to discover how Leading Edge can bring your ideas to life with precision and excellence.

Dongguan, Guangdong, China

Phone : +86 13826962122