OUR SERVICES

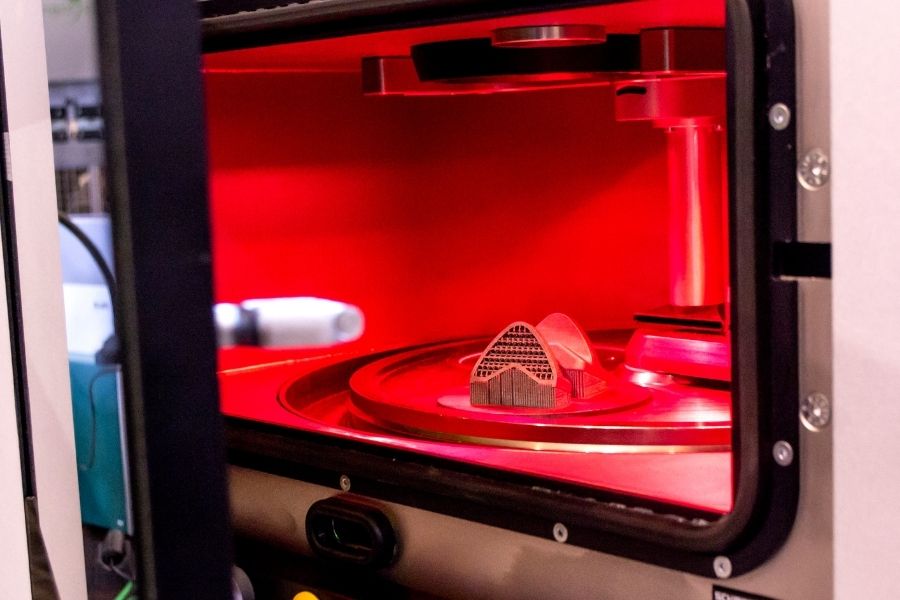

Rapid Prototyping

Turn your ideas into reality with Leading Edge’s industry-leading rapid prototyping services. Our advanced manufacturing techniques and expert engineering team help you develop, test, and refine your designs quickly and efficiently, empowering innovation and reducing time to market.

Capabilities

Our capabilities

Rapid prototyping is the process of creating physical models of a design using advanced manufacturing technologies. It enables designers and engineers to visualize concepts, test functionality, and identify potential issues early in the product development cycle. This iterative approach helps accelerate decision-making and enhances product quality.

- Stereolithography (SLA): High-resolution prototypes with smooth surface finishes, perfect for intricate designs.

- Selective Laser Sintering (SLS): Durable, functional prototypes using nylon-based materials.

- Fused Deposition Modeling (FDM): Cost-effective models for conceptual visualization and basic testing.

- Direct Metal Laser Sintering (DMLS): Complex metal prototypes for aerospace, automotive, and medical applications.

- High-Precision Prototypes: Produce parts with tight tolerances and exceptional accuracy.

- Material Versatility: Wide selection of metals and plastics to simulate end-use products.

- Quick Turnaround: Advanced machinery enables efficient production for rapid iterations.

- Custom Metal Prototypes: Sheet metal bending, forming, and cutting for durable and functional components.

- Small-Batch Capabilities: Cost-effective solutions for low-volume prototype runs.

- Low-Cost Replicas: Create small batches of high-quality plastic parts using silicone molds.

- Material Flexibility: Simulate production materials like ABS, PC, or TPU for functional testing.

- Rapid Tooling: Produce prototype molds to test designs before committing to mass production.

- Functional Testing: Evaluate fit, form, and function using production-grade materials.

Material

Our materials

At Leading Edge, we provide a wide range of materials for your needs.

Lightweight, corrosion-resistant, and highly machinable, aluminum is a versatile material used across aerospace, automotive, and consumer electronics. Its excellent thermal conductivity and ease of anodization make it ideal for heat sinks, housings, and structural components. Common grades:

- 6061-T6: Excellent general-purpose alloy, ideal for precision parts

- 7075-T6: High-strength aerospace-grade applications

- 5052: Excellent corrosion resistance, marine applications

- 2024: Aircraft structural components

- QC-10: Premium mold-making aluminum

Known for its exceptional strength and corrosion resistance, stainless steel is a go-to material for medical, food processing, and industrial applications. Its durability and resistance to extreme temperatures make it ideal for surgical instruments, valves, and automotive exhaust systems. Common grades:

- 304/304L: General purpose, good corrosion resistance

- 316/316L: Medical and marine grade

- 17-4 PH: High-strength, heat-treatable

- 440C: High hardness applications

- 321: High-temperature stability

- 420: Cutlery and surgical instruments

Valued for its strength and affordability, carbon steel is a popular choice for mechanical parts, fasteners, and heavy-duty components. Its ability to be hardened and tempered makes it suitable for applications requiring high wear resistance. Common grades:

- 1018 (easily machinable)

- 1045 (medium carbon), and A36 (structural).

Tool steel is known for its wear resistance, hardness, and ability to hold a sharp edge. It is ideal for cutting tools, molds, and dies. Common types include:

- D2: High wear resistance, cutting tools

- H13: Hot work applications

- A2: Cold work applications

- O1: Oil-hardening applications

- M2: High-speed steel

- P20: Mold and die applications

Copper offers exceptional thermal and electrical conductivity, making it essential in heat exchangers, electrical wiring, and PCB components. Its antimicrobial properties also make it suitable for medical and food processing applications. Common grades of copper alloys:

- C360 Brass: General purpose

- C954 Bronze: Marine applications

- Beryllium Copper: Spring applications

- Phosphor Bronze: Bearing applications

- Tellurium Copper: High conductivity

- Naval Brass: Marine components

Combining lightweight properties with extraordinary strength and corrosion resistance, titanium is used in aerospace, medical implants, and high-performance automotive components. It is biocompatible, making it a preferred material for prosthetics and surgical tools. Common grades:

- Ti-6Al-4V (Grade 5): Aerospace and medical

- Ti-6Al-4V ELI: Medical implants

- Grade 2: Pure titanium, chemical resistance

- Grade 4: Higher strength pure titanium

- Ti-6Al-7Nb: Medical applications

- Beta titanium alloys

- Inconel 718: High-temperature applications

- Hastelloy: Corrosion resistant

- Monel: Marine applications

- Kovar: Thermal expansion matching

- Invar: Dimensional stability

- MP35N: High-strength medical

- PLA (Polylactic Acid): Eco-friendly, cost-effective material for prototypes and visual models.

- ABS (Acrylonitrile Butadiene Styrene): Durable and impact-resistant, ideal for functional prototypes and industrial parts.

- Nylon (PA12): Strong, lightweight, and wear-resistant, commonly used in mechanical parts and consumer goods.

- Polycarbonate (PC): High impact strength and heat resistance for automotive and industrial applications.

- Flexible TPU: Elastic and wear-resistant, ideal for seals, gaskets, and ergonomic parts.

- PEEK (Polyether Ether Ketone): High-performance plastic for aerospace, medical, and high-temperature applications.

- Carbon Fiber Reinforced Polymers: High strength-to-weight ratio for structural applications.

- Glass-Filled Nylon: Enhanced stiffness and durability for demanding environments.

Why Us

Why choose us

At Leading Edge, we pride ourselves on engineering, delivering unparalleled quality, tailored solutions, and exceptional customer support.

Rapid Turnaround

Experience quick prototype-to-production transitions with our streamlined workflows. We typically deliver orders within 2-4 weeks, depending on complexity and quantity.

Design Flexibility

Make design modifications easily without the constraints of high-volume tooling. Our agile manufacturing approach accommodates design iterations and improvements.

Quality Assurance

At Leading Edge, we prioritize quality in every aspect of our manufacturing process. Each component undergoes rigorous quality checks to ensure it meets the highest standards of performance and reliability.

Cost-Effective Production

Minimize your investment in tooling and inventory while maintaining high quality. Our efficient processes and lean manufacturing principles help reduce costs without compromising precision.

With Leading Edge, you’ll find more than a manufacturer—you’ll discover a committed partner for achieving your most ambitious goals.

Ready to get started?

Let Leading Edge be your trusted partner for precision CNC milling. Our expertise, advanced technology, and commitment to quality ensure that your parts are manufactured to the highest standards. Contact us today to discuss your project or request a free quote and learn how we can bring your designs to life with exceptional precision.

How it works

When you need experience, we have it covered.

Our streamlined process ensures precision, efficiency, and complete satisfaction at every step.

Consultation what you need.

Our engineering team carefully reviews your CAD files, technical drawings, and specifications, engaging in detailed discussions about material choices, tolerance requirements, and surface finish needs.

Quote and Order Confirmation

You’ll receive a comprehensive quote that includes all specifications, deliverables, quality standards. Upon your approval, we move into the confirmation phase where all project details are thoroughly reviewed and finalized.

Manufacturing & Quality Control

During production, we maintain rigorous quality control through continuous monitoring and inspection processes. Our state-of-the-art CMM equipment verifies critical dimensions, while expert technicians conduct thorough surface finish inspections.

GET IN TOUCH

Whenever you need us, we’re here for you.

Got a project in mind? Contact us today to discover how Leading Edge can bring your ideas to life with precision and excellence.

Dongguan, Guangdong, China

Phone : +86 13826962122